Rice Husk Pellet Mill

Rice Husk Pellet Mill is widely used to process wood materials(wood,biomass,rice Hulls,corn Straw,sawdust,wood Shavings,tree Bark,peanut Hull,crop Straw, etc.)into pellets,which used as fuels. It is in accordance with green technology and improves the wood materials recycling ratio. The pellet mill produced by our company is featured with high production performance and low energy consumption.

Rice Husk Pellet Mill

Pellet Mill Series

Pellet Mill Production Line

Processing material:wood,biomass,rice Hulls,corn Straw,sawdust,wood Shavings,tree Bark,peanut Hull,crop Straw, etc.

Equipment configuration:A complete pellet mill production line for making pellets including: Raw materials preparation, material crushing, drying (if the raw material contains moisture of more than 18%), pellets pelletizing, pellet cooling, pellets packing.

Production Process of Complete Pellet Mill Production Line

Raw materials preparation, material crushing, drying (if the raw material contains moisture of more than 18%), pellets pelletizing, pellet cooling, pellets packing.

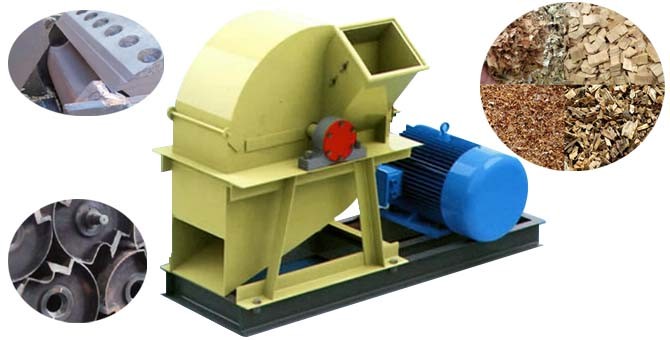

1.Crushing Process: Because of the best size of raw materials in pelletizing is 3-5mm. So, based on different materials, wood crusher is necessary. After the material being crushed by wood crusher, the output size can be diameter3-5mm that is suitable for further processing.

2.Drying Process: The best moisture content to pelletizing is about 11-17%. So before pelletizing, a drying machine is needed to make the moisture content reaches the required standards.

3.Pelletizing Process: After crushing and drying, the raw materials can be put into wood pellet mill, wood pellet mill is the significant part of the wood pellet production line, and has reliable and stable performance. Capacity ranges from 1T to 10T per hour.

4.Cooling Process: After pelletizing process, the temperature of wood pellets is between 60-80 degrees and the moisture content is close to 15%. So a cooler must be used to reduce their surface temperature and the moisture content which makes the wood pellets easy to store, meanwhile helps screen good and pure pellets.

Advantages of Pellet Mill Production Line

1. Simple and reasonable structure, easy maintenance and reliable performance;

2. Equipped with automatic lubrication system that is energy efficient;

3. Ring die can handle almost all of the agricultural wastes and crop straws;

4. Energy saving, in line with green technology, environmental prtection

Customer Case

-

6t/h Wood pellet production line

Wood pellet production line can process the wood and sawdust into pellets for further usage. It is with high performance and low energy cost.

-

1-8t/h Sawdust Pellet Production Plant

It is professionally used for sawdust material pelletizing. It uses the agricultural wastes such as the sawdust as raw material, through grinding, pressing process, achieving solid biomass fuels that can burn directly.

-

8t/h Complete Biomass Pellet Machine

Biomass pellet mil is a pellet forming machine regarding corn stalks, cotton stalks, straw stalks, sawdust, peanut shells,bark and other agricultural wastes as raw materials. Its products are widely used in fireplaces, boilers, biomass power stations etc.

-

10t/h Straw Pellet Mill

Straw pellet mil is mainly used for processing crop straw into cylindrical pellets. According different characteristics of the raw materials, the finished products can be used as biomass fuel or animal feed.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

Auxiliary equipment

Related Information

- Straw pellet production equipment

- Pellet Mill For Sale

- Ring Die Pellet Mill

- Small Pellet Mill

- Pellet Mill Manufacturers

- Pelleting Machine Manufacturers

- Pellet Mill Equipment

- Pellet Mill Press Machine

- Pellet Making Machines

- Feed Pellet Mill

- Wood Pellet Mill For Sale

- Wood Pellet Machine For Sale

- Wood Pellet Maker

- Wood Pellet Manufacturing Equipment

- Biomass Pellet Mill

- Biomass Pellet Machine

- Biomass Pellet Making Machine

- Biomass Pellet Maker

- Sawdust Pellet Machine

- Sawdust Pellet Mill

- Sawdust Pellet Maker

- Straw Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill - Fote Machinery

- Solution for Making Pellets from Rice Husk

- rice husk pellet mill,pellet machine,flat die pellet

- Rice Husk Pellet Mill Makes Pellets Fuel From Rice Husk

- Rice Husk Pellet Machine

- 2T/H Rice Husk Pellet Plant

- Rice husk pellets price suppliers manufacturers

- Fote Rice Hulls Pellet Mill Get Essence From Advanced Technology

- Rice Husk Pellet Machine and Pellet Plant

- machine to make rice husk ash pellets

- rice husk pellet mill/paddy husk pellet equipment

- Rice Hull Pellet Mill,Pelletizing Rice Husk

- Rice Husk Pellet Mill/ rice husk pellet making

- Rice Husk Pellet Mill Deserves Your First Choice

- Wood Shavings Pellet Mill

- Wood Biomass Pellet Mill

- Peanut Shell Pellet Mill Machinery

- Best price peanut shell pellet mill

- Tree Bark Pellet Mill Machine

- Tree bark pellet making machine

- Wood Bark Pellets

- Ring Die Wood Pellet Mill

- Production Process Wood Pellet From Wood Biomass

- Biomass Pellet Maker

- Best price complete pellet mill line

- Corn Stover Pellet Mill

- Corn Stover Pelleting Machines

- Wood Bark Pellets

- China Corn Stalk Pellet Machine Wood Pellet Press

- Straw Pellets Making Solution

- Can straw pellet mill make pellet from wood

- Ring Die Wood Pellet Mill

- Corn Stover Pellet Mill

- Small Diesel Wood Pellet Mill

- large wood pellet mill,corn straw pellet press,grass pellet

- Sunflower Seed Shell Pellet Mill

- Sunflower Seeds Hull Pellet Mill Is Selling Well

- Sunflower Seed Shell Pellet Mill

- wood pellet mill/Sunflower seed shell pellet mill machine