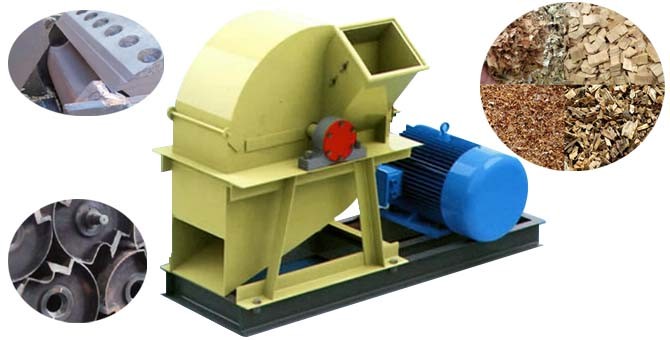

How to choose wood pellet mill?

If you want to start medium or large size wood pellet plant for commercial use, there are three aspects for you to consider firstly:

1. Working efficiency: ring die pellet mill is highlighted with high efficiency and large capacity. Ring die pellet mill has wide application in commercial use with relatively large production capacity, 300~3500 kg/h. While flat die pellet mill is popular with home use, capacity is from 30-2000kg/h.

2. Pellets quality: biomass pellets produced by ring die pellet mill are more solid and smooth. Ring die pellet mill can be applied to making various biomass materials into pellets, especially for materials hard to be pelletized or with much moisture.

3. Economic profits: though ring die pellet mill is relatively more expensive, while compared with its long service life and low-malfunction rate, it is really a cost-effective machine.

Operating Instructions of Ring Die Pellet Mill

1. Have a better understanding of the pellet mill structure and performance, and strictly follow the operation instructions and professional technical personnel’s guidance.

2. Pay attention to regular maintenance so as to extend the service life of pellet mill.

3. The operator should stay at the working area while pellet mill is under running condition.

It will be better to choose appropriate pellet mill according to different raw materials and capacity requirements.