Cotton Stalk Pellet Mill

Cotton stalk pellet mill uses the agriculture wastes such as cotton stalk as raw material to produce pellets through crushing, pressing, and moulding. The moulded particles are a new type of biological energy source, which can take the place of raw coal, fuel oil, liquefied gas, etc.

Get a Quote

Chat Online

Introduction of cotton stalk pellet mill

Cotton stalk pellet mill uses the agriculture wastes such as cotton stalk as raw material to produce pellets through crushing, pressing, and moulding. The moulded particles are a new type of biological energy source, which can take the place of raw coal, fuel oil, liquefied gas, etc. It is widely applied in industrial boiler, biomass power plant, etc. This cotton stalk pellet mill is a compression molding device of low investment, quick profit and low risk.

Depending on our strong technology power, we continuously renovate and develop the cotton stalk pellet mill, keeping its technology staying an international advanced level. Its ring-die is manufactured by high grading and high nickel stainless steel, which improves the finished product quality and prolongs the service life. Cotton stalk pellet mill has two layers of die, which can be divided into the up and down two parts. Therefore, users can chose the pore diameters of different specifications, and produce different particle finished products. Besides, the bearing of the particle moulding system is high quality silent bearing which operates more safely and environmentally.

Advantages of cotton stalk pellet mill

1. Compact structure, advanced designation.

2. Unique compression ratio, low production cost.

3. Big finished product particle proportion, small volume.

4. Durable burning finished products, convenient transmission and storage.

5. Recycling cooling and lubricating system, environmental and energy saving.

6. Exquisite manufacture, reliable performance.

-

For Detailed Specifications,Please Click Here

-

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

|

Model

|

Power(Kw)

|

Pellet Specification(mm)

|

Capacity(t/h)

|

|

FKL55

|

75

|

φ4-φ12

|

0.8-1.5

|

|

FKL56

|

90

|

φ4-φ12

|

1.2-1.8

|

|

FKL58

|

160

|

φ4-φ12

|

1.8-2.1

|

|

FKL68

|

160

|

φ4-φ12

|

2-2.5

|

|

FKL85

|

220

|

φ4-φ12

|

2.5-3.5

|

|

FKL88

|

315

|

φ4-φ12

|

3.5-4.5

|

|

FKL105

|

360-450

|

φ4-φ30

|

5-8

|

|

FKL125

|

550-660

|

φ4-φ30

|

8-12

|

Totop

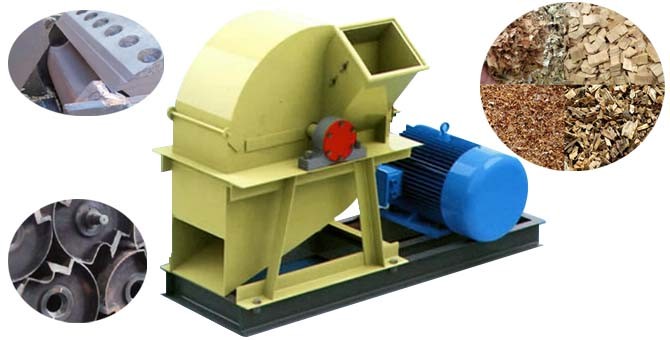

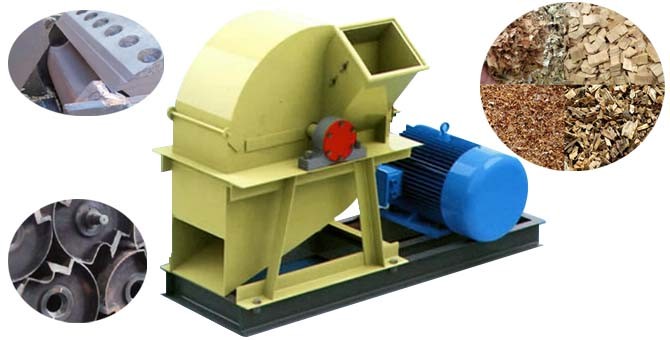

Hammer crusher is used for crushing small diameter raw materials, which are no more than 50mm such as corn straw, grain, tree branches, and bamboo and so on. After crushing, the diameter of the final products could be 3-5mm which is the optimal size for pelleting or briquetting. Featured with convenient operation and high efficiency, this electric hammer mill is the first choice for farm, middle sized feeding factory and family.

1.Long service life.We adopt mew technology to make hammers and make them wear-resisting and impact resistant.

2.Reasonable design,compact structure and less wearing parts.

3.Low energy consumption, High Abrasion Resistance and environment friendly.

Wood hammer mill can be used to crush hard, soft and weakly corrosive materials. After crushing, raw materials are uniform and with proper moisture content to meet further processing. It is the impacting effect that makes hammer mill crush materials. Wood materials are impacted by high speed rotary hammers as soon as they enter the hammer mill. The broken materials strike repeatedly with the rotating hammers.There are spaces where crushed materials are squeezed out. Because of the reasonable design and high quality materials, wood hammer mill works in a stable way.

Wood hammer mill is popular with many industries and we recommend it as well if you are considering biomass industry investment. Biomass fuel takes wood chips, wood sawdust, peanut stalks, corn straws and so on as materials and wood hammer mill can crush these materials into 3mm-5mm wood materials for pellet mill use.

Wood Pellet production, Feed Pellet production,Wood Briquette production

Rotary Drum Dryer is generally suitable for drying granular materials, and can also be used for drying sticky and paste material by doping partially other material. It decreases the humidity of all kinds of biomass materials efficiently. It is a kind of new drying device that is developed by our company in allusion to the latest requirements in the drying machine market. It saves the energy and the drying cost to the maximum, and is widely used by new biological energy source and farming enterprises.

1.Large drying capacity, high heat protection effect.

2.Low fuel consumption, outstanding energy-saving effect.

3.Stable barrel operation, high stability.

4.High temperature resisting, strong over-load ability.

5.Low pollution, excellent environmental effect.

pellets come from pelletizer need to be cooled down to keep a better strength. The sieve will separate intact pellets from ash, which could be in recycling use.