Bagasse Pellet Mill

Pellet Size:The length and diameter of pellets are adjustable

Application Range:Producing wood pellets, sawdust pellets, straw pellets, log pellets and other agriculture wastes pellets.

Bagasse pellet mill is used to produce pellets fuel from sugar cane bagasse. What makes bagasse pellets superior to other kind of fuels is its renewability.

What makes bagasse pellets superior to other kind of fuels is its renewability. As energy shortage is increasingly serious, seeking renewable energy and alternative fuels becomes a hot topic. Being a kind of fuel with the longest history, biomass fuel receives its burgeoning again now.

Different from traditional one, bagasse pellets are made from sugar cane wastes that are widely distributed after harvest of sugar cane on the farm. In particular, bagasse is the appropriate available resource.

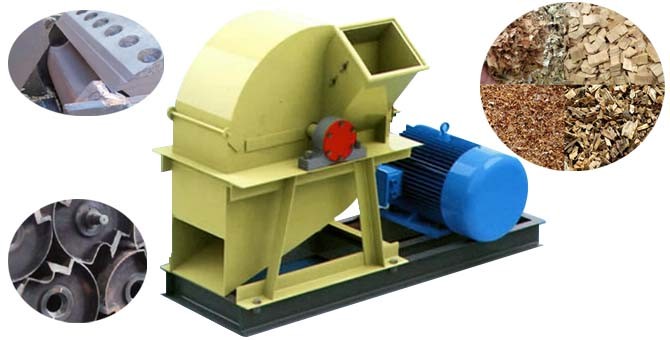

Introduction of Bagasse Pellet Mill:

Bagasse pellet mill can process bagasse into a certain size, by compressing and heating methods, the original amorphous and dispersed material is compressed into a regular shape, which is made into solid pellet with large density. After drying, compression and molding, its density, durability and combustion characteristics have been a qualitative improvement, which greatly improves the grade of bagasse, and it also becomes convenient for transportation and storage. Bagasse pellet mill also can be called waste sugar bagasse pellet machine.

The Advantages of Bagasse Pellet Plant:

1. Wide material source: crop straw, dry leaves, sawdust, weeds and other combustible agricultural waste can become its raw materials.

2. The cost price is low: low cost of raw materials, small investment of the equipment, the operation is simple. The idle human labor in rural areas after simple training can operate the equipment, the human labor cost is very low.

3. Wide application ranges: bagasse brick and bagasse particles are easy to use, the family unit is also applicable; the burning effect is good, which can meet the cooking, heating, bathing needs, especially the necessities for biomass power plant.

4. Environmental benefits: it turns waste into treasure, namely increases the income of farmers, but also protects the environment, solves the bagasse disposal problem of the governments at all levels, which has won the national policy support!

5. Rich return of the investment: when coal prices fluctuate, invest and set up factories for producing bagasse pellet fuel has no risk and high profit, and there will be an unexpected effect.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment