Peanut Shell Pellet Mill

Peanut shell pellet mill is predominantly used for processing peanut shell into particles. The formed particles have high density and uniform size, which is easy to store and transport. The finished products are often used in power plants, boiler combustion for warm, and so on, which is waste utilization and energy conservation.

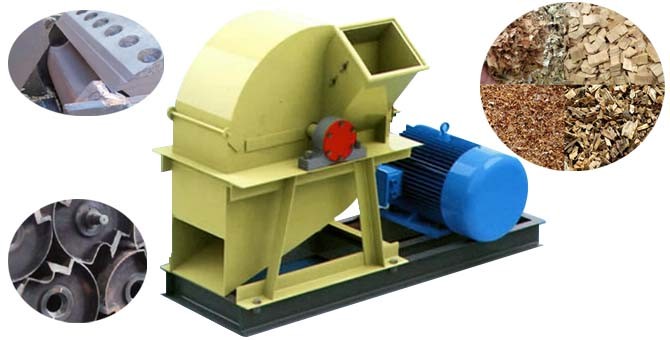

Introduction of peanut shell pellet mill

After being processed, the peanut shell can not only realize the environmental protection, but also improves the utilization ratio. The finished product is commonly seen in biomass fuel plants, biomass boilers, power plants and other industries.

The lubrication of roller’s bearing is independently and automatically supplied oil by circulation pump, which can protect the bearing well and avoid any damages because of forgetfulness and laziness. It has the advantages of low energy consumption, reasonable design, durability and so on. The key parts of the peanut shell pellet mill template and pressure roller that are both made of high quality alloy steel. So that its service life is longer 5-7 times than other common pellet mill produced by other manufacturers. All the parts of peanut shell pellet mill is made and assembled by ourselves to avoid external quality problems because of manufacture. Besides, we have spare parts storage with a full set of accessories, which plays a key role in equipment maintenance for customers to shorten time and reducing the loss.

Advantages of peanut shell pellet mill

1. It has radiator itself, so that it can work 24 hours without stopping.

2. Two-layer dies endure it a double life, improving yields and reducing costs.

3. The die is vertical installed, so that materials can flow freely.

4. The operation is instable, so it can be directly placed on the ground. Its installation is easy.

5. Big reducer, large pressure, so that the mold is hard to jam.Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment