Rice Straw Pellet Mill

Voltage:380V,50Hz

Working:22 hours continue working

Final Pellets Length:20-50mm (Adjustable)

Raw Materials:Rice straw, rice husk, hard wood, palm fiber, sawdust, alfalfa and other biomass

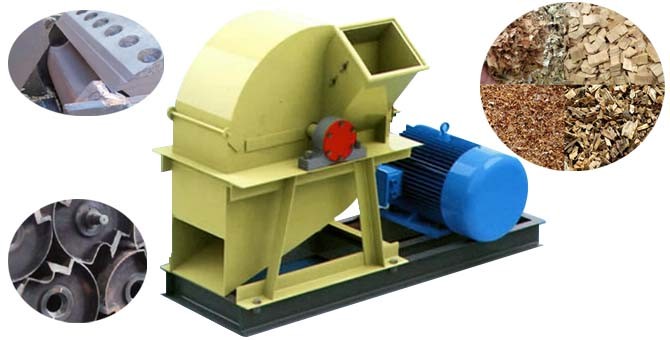

Rice straw pellet mill is a kind of pelleting press machine that is professionally designed to process straws. After being processed, the rice straw pellets is generally used as fuels,which is in line with green technology.

Rice straw pellet mill is a new type energy device that is professionally used for rice straw particle pelleting. It is developed by introducing German technology. Its die owns up and down two parts, therefore, it can produce particle finished products of two different specifications by choosing two different bore diameters. The pinch roller pf the rice straw pellet mill uses cone, which reduces the dislocation friction of the wheel and die, and decreases the kinetic energy loss. Besides, this device adopts screw center pressure regulating structure, of which the die interval can be adjusted to be suitable for different material, thus guaranteeing the suppress effect. The rice straw pellet mills produced by Henan Fote Heavy Machinery Co.,Ltd., pass through the country patent, satisfy customer’s different requirements, and bring maximum economic benefit for you.

Applied Materials of Rice Straw Pellet Mill:

In addition to process the ordinary straw, rice straw pellet mill also can suppress crop straw, such as corn stalks, wheat straw, cotton stalk, furniture factory waste, rice husk, peanut shell, palm, coconut shells, melon seed shell, grass and other materials. There are many other raw materials it can process, if you want to know the details, please contact our professional customer service!

Rice Straw Pellet Fuel Machine Production Process:

Cut the straw or hay into 30 mm segments, control the moisture content within the range of 15~25%. Transfer the materials into the spiral feeding device via the conveyor, and then the screw feeding machine strengthens the material into the feeding port of rice straw pellet machine. Finally, the material is forced to be extruded from the die after molding, which can be made into various different shapes. After cooling (the moisture content is not more than 14%), it can move to the packaging process.

Rice Straw Pellet Making Plant Advantages:

1. High efficiency.

It adopts the gear transmission system, which has ideal transmission ratio, large driving torque and stable transmission;

It has the preparation of ring die with multi aperture and thickness betweenΦ6~Φ10, customers can choose the suitable one according to different needs, in order to obtain the best technical and economic benefits.

2. Intelligent.

It adopts advanced frequency conversion motor to feed, which is also provided with an overload protection device as well as a magnetic sheet iron removing device; High yield, low noise, convenient operation and repair.

3. Quality assurance. We will arrange related personnel to guide the troubleshooting, debugging and repair and other specialized training for customers. During the production process of the pellet mill, we will do regular visit to customers for feedback and improvement, and we will also consult the user on the quality of products, the production conditions and other various aspects of the equipment, so as to strive to make the comprehensive performance and further improvement of the product qualityYour Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment