Rice Husk Pellet Mill

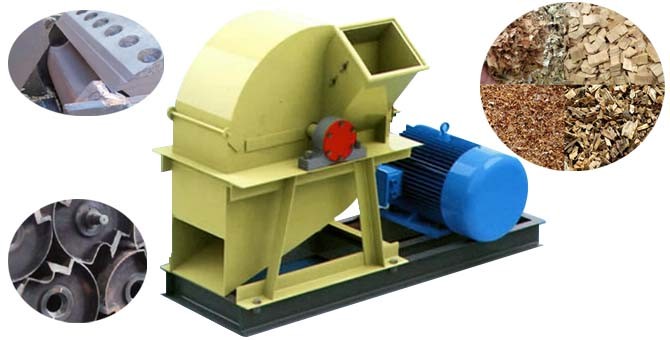

Rice husk pellet mill is a machine to press rice husk into pellets. Rice hull particulates processed by rice husk pellet mill have high combustion value, long burning time and they are environmental protection. Rice husk pellet mill absorbs the essence of foreign pellet mill. Its key component "two-layer mould" has unique structure.

Introduction of rice husk pellet mill

Rice husk pellet mill is a machine to press rice husk into pellets. Rice hull particulates processed by rice husk pellet mill have high combustion value, long burning time and they are environmental protection. it is an ideal compression molding machine with small investment, quick effect, and risk-free.

Its "pinch roller" is made of high alloy wear-resistant material, so its service life is longer several times than the similar other machine’s. The grease of its transmission system can be automatically filtered, so its lubrication effect is very well. Rice husk pellet mill is characterized by unique design, reasonable structure, high efficiency, long service life, etc.

Advantages of rice husk pellet mill

1. Vertical feeding method, so that raw materials can be directly in place.

2. Its mold is static, so that materials can evenly distribute on it.

3. The automatic lubrication system can protect the equipment every minute.

4. Ring molds with vertical structure is conducive to the heat dissipation.

5. The separate discharge device can ensure the forming rate of materials.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment