Biomass Pellet Machine

Biomass pellet machine is a pellet forming machine regarding wood, sawdust, biomass, corn stalks, cotton stalks, straw, peanut shells, rice husks, bark and other agricultural wastes as raw materials. Its products are widely used in fireplaces, boilers, gasifiers, biomass power stations etc.

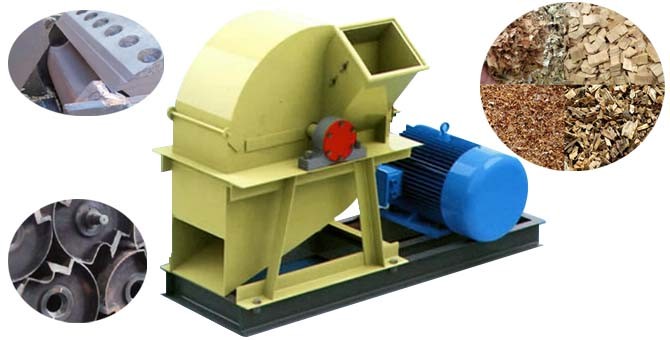

Introduction of biomass pellet machine

Biomass pellet machine, also named biomass pellet maker, is widely used to transfer the biomass to biofuel. The driving gear of biomass pellet machine adopts high precision gear transmission. Its reducer adopts famous brand. Its ring die is as thick as 6-8mm. So its working performance is reliable and stable. Besides, the ring die and roller of biomass pellet machine (biomass pellet maker) are forged of alloy steel. Their wear-resistance is average improved almost twice times than the old ones made by thermal technology, which can maximize saving production costs. Work principle: when biomass pellet machine works, the main motor drives reducer, and then the reducer drives the roller though spindle. There is ring die on the round of the roller. Sawdust, straw powder, wood powder, and other raw materials enter into the rollers. Materials are pressed by the two rollers with a big pressure, and then they are squeezed out from holes of the die. At the last, the finished products are discharged from the suppressed room by material dialing disc.

Advantages of of biomass pellet machine

1. The steel plate of the base frame is as thick as 20mm, durable and stable.

2. The main spindle adopts dust extraction with cool air, reducing dust powder.

3. The equipment uses automatic lubrication system, which can automatically inject lubricating oil during work.

4. The ring die is installed vertically, which can effectively use the centrifugal force produced during rotation to increase the yield.

5. The ring die is composed of up and down two parts, so that we can turn it around and reuse it after it is partly worn, greatly reducing costs.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment