Ring Die Pellet Machine

Yield: 0.5-2t/h

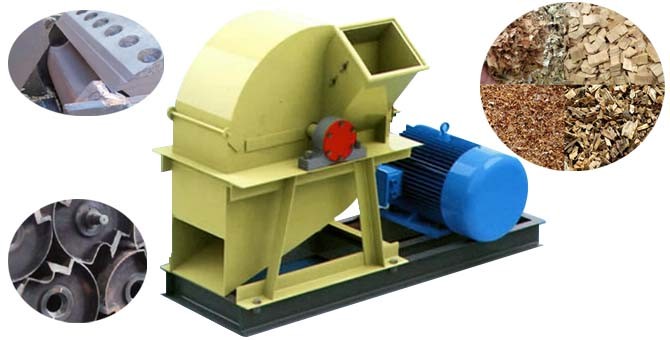

Feed Size: Powder-50mm

Pellet Size: According to requirements of customers

Ring die pellet machine is also called ring die pellet mill, which is the core equipment in pellet manufacturing industry. It includes vertical ring die pellet machine and horizontal ring die pellet machine, which belongs to one kind of biomass pellet machines. The produced particles are efficient, environmental protection, easy combustion and high calorific value. When compared with the traditional fuel, it has more advantages, which can replace the coal particles in daily life; the particles are clean and easier to store and transport.

Ring die pellet machine is also called ring die pellet mill, which is the core equipment in pellet manufacturing industry. It includes vertical ring die pellet machine and horizontal ring die pellet machine, which belongs to one kind of biomass pellet machines. The produced particles are efficient, environmental protection, easy combustion and high calorific value. When compared with the traditional fuel, it has more advantages, which can replace the coal particles in daily life; the particles are clean and easier to store and transport.

Ring Die Pellet Mill Features:

1. The diversified treatment of materials, high yield, low price, low power consumption, simple operation.

2. The annular mould, vertical structure, which is conducive to the radiation and cooling of granulating chamber.

3. It uses high precision cylindrical helical gear direct drive, and the high drive efficiency can reach above 98%.

4. It can adapt to a variety of biomass feedstock, the material from powder to the length of 50mm with water content of 10-25% can mold.

5. It adopts the principle of the interaction friction and extrusion between pressing wheel and the mould to mold materials into pellet shape, so that the materials will not stuffy the machine, which can ensure the forming stability of the materials.

6. The pellet forming system uses high-quality silent bearings, and it increases the injection cooling system when it is running, so that the bearing service life is longer, operation is more secure.

The Correct Using Methods of Ring Die Pellet Machine:

1. For the initial use of the machine, it needs to use the oil to clean a few minutes to 20 minutes, which can increase the discharging speed, it also has good effect on the material surface.

2. It can avoid the hard impurities mixed in the materials, which may results in the rupture of ring die.

3. After using, clean the machine to ensure the normal use for next time.

4. The ring die must be stored in a dry and clean place, and make a good specification mark.

5. Regular inspection.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment