Coconut Shell Pellet Mill

Coconut shell pellet mill can process the coconut shell material efficiently. After processing, it can increase material’s density, which will make it convenient for usage and transportaion. The pellet mill is widely applied in industries such as bio-energy, farming, forestry, etc.

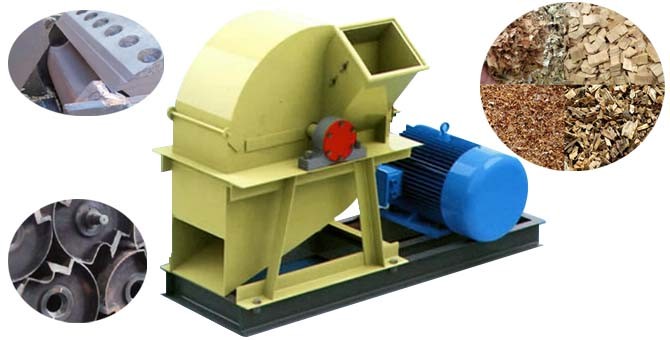

Introduction of coconut shell pellet mill

Coconut shell pellet mill is a high performance device that is specially designed for coconut shell pelleting. It is equipped with fully automatic heating device which can be used to adjust the material humidity. Coconut shell materials are fed into the device evenly, solving the blocking phenomenon and improving the briquetting ratio. The coconut shell pellet mill texture is titanium alloy steel and stainless steel of better stiffness and toughness, which makes the device more wearable, prolongs the service life, and decreases the cost. The diameter of the finished product particle ranges from 3mm to 12mm, and the output per hour varies from 1500kg to 2800 kg. Henan Fote Heavy Machinery Co.,Ltd., is a professional large scale manufacture that researches, develops, manufactures and sells pellet mill machines in China. Our coconut shell pellet mills pass through strict and standard production and technical management, and are your ease choice. Coconut shell pellet mill is of high production and low power consumption. It brings high economic benefit for users, and is a necessary device for modern coconut shell process.

Advantages of coconut shell pellet mill

1. Superior quality, high particle rate.

2. Vertical feeding, convenient production.

3. Reasonable design, simple structure.

4. Excellent heat dissipation function, low power consumption.

5. Perfect performance, low failure rate.

6. Wear resisting, long service life.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment