Sunflower Seed Shell Pellet Mill

Sunflower seed shell pellet mill, one of the main pellet mills of our company, is specially used for the pressing and moulding operations of sunflower seed shell material. This device is a multi-function pellet mill that is successfully improved and renovated on the basis of bringing in international advanced pelletizing technology.

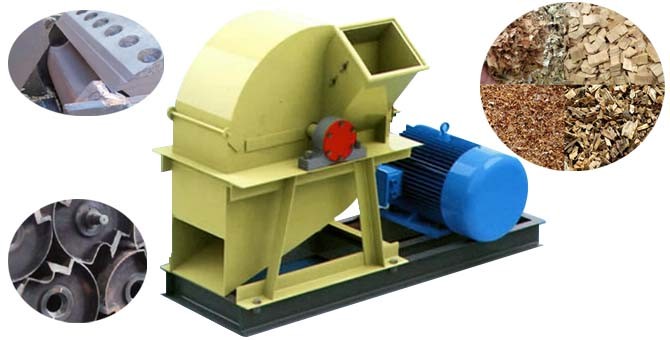

Introduction of sunflower seed shell pellet mill

Sunflower seed shell pellet mill adapts to international biomass energy regeneration demand, and brings production convenience and economic benefit for users.

Sunflower seed shell pellet mill has international advanced level, and is sold throughout the country and oversea market. Its core part is the double-layer die assemble of unique structure. The pinch roller is manufactured by using high alloy wear resisting material, and it can operate continuously for more than 20 hours. The main engine box is precisely processed by CNC machining center imported from Switzerland, decreasing the processing error to zero and providing strong support for the normal operation. Sunflower seed shell pellet mill is directly driven by high precision cylindrical helical gear, of which the transmission efficiency reaches up to over 98%. Henan Fote Heavy Machinery owns two large scale production bases. This sunflower seed shell pellet mill is the most stable, efficient and economic equipment that is finally determined through hundred times of experiments and demonstrations, and it is worthy of your trust.

Advantages of sunflower seed shell pellet mill

1. Excellent pressing effect, energy saving and efficient.

2. Reasonable structure, unique designation.

3. Even set compression roller, stable operation.

4. Anti-fatigue parts, high wear resisting performance.

5. Multiple functions, high efficiency.

6. Huge profit space, high economic benefit.

Your Enquiry

If you’re in need of a Pellet Mill or Production Line you’ve come to the right place. Whether you know exactly what you need, or are in need of some guidance, we are here to help. Please feel free to contact us via Email or filling in the following form.

Pellet Mill

- Wood Pellet Maker

- Biomass Pellet Machine

- Pellet Mill Press Machine

- Sawdust Pellet Mill

- Straw Pellet Machine

- Rice Husk Pellet Mill

- Peanut Shell Pellet Mill

- Coconut Shell Pellet Mill

- Cotton Stalk Pellet Mill

- Sunflower Seed Shell Pellet Mill

- Rice Straw Pellet Mill

- Bamboo Pellet Mill

- Bagasse Pellet Mill

- Ring Die Pellet Machine

Auxiliary equipment